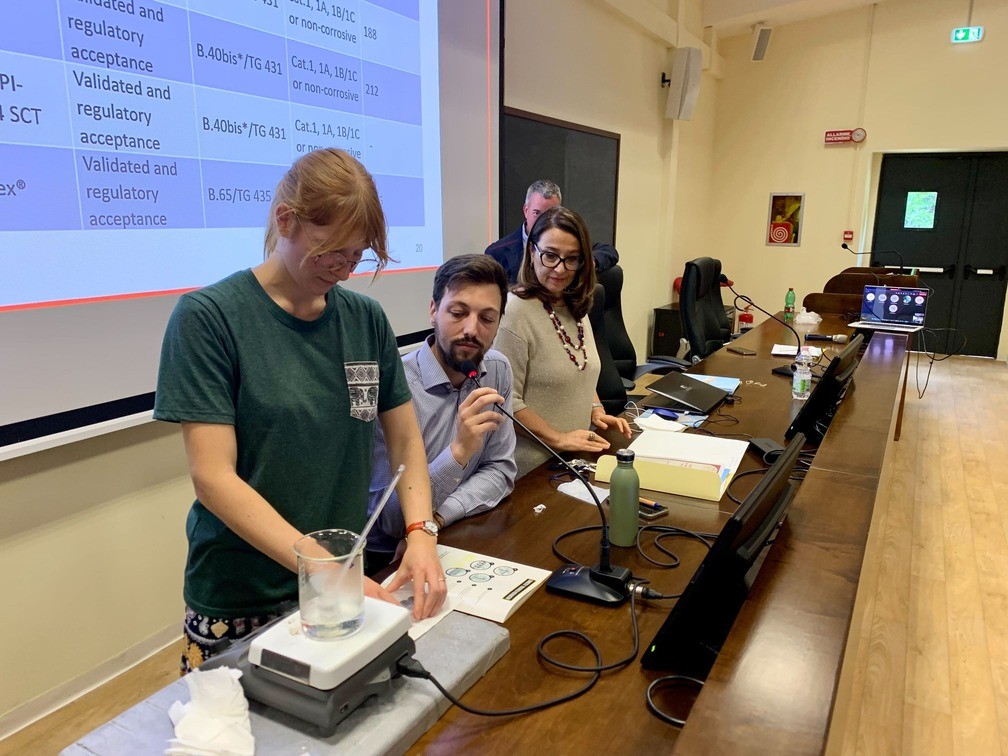

On the 30th of May INT.E.G.RA. and Corrositex® in vitro tests and the Irritection Assay System arrived at the University of Naples Federico II for the ‘INT.E.G.RA Introduction Day’ on in vitro methodology and the OECD 435 Corrositex® corrosion test.

More than one hundred students of the Chemistry and Pharmaceutical Technology masters were introduced to the methods, which are among the most widely used NAM methods due to their ease of use, identification capability and the only OECD Test Guidelines to be completely animal-free.

The 100% animal free OECD skin corrosion test

Corrositex® OECD TG 435 identifies corrosive chemical substances and mixtures (UN GHS Cat.1) and their sub-category 1A, 1B and 1C by means of an artificial membrane designed to respond to corrosive substances in a manner similar to animal skin in situ.

- Globally accepted and recognized

- Results in as little as 3 minutes and no more than 4 hours

- Easy to use

- 100% animal free

- No need for a cell biology or cellular coluture lab

- Long storage period

- Easily stored

The only one able to identify sub-categories 1A, 1B and 1C

TG OECD 431 only allows discrimination between Sub-cat. 1A from those 1B and 1C.

TG OECD 430 is unable to discern between any subcategories.

Only Corrositex® OECD 435, among all alternative in vitro methods OECD adopted, is able to identify and classify the Cat.1 sub-category of the test substance.

The Assay System

The Corrositex® Assay System consists of a glass vial filled with a chemical detection fluid coated with a proprietary membrane that acts as a bio-barrier, the system is designed to mimic the effect of corrosives on living skin.

How does it work?

Corrositex® is performed in three steps:

1. First, a qualification test is performed to ensure that the test sample and CDS reagent are compatible. If a physical change or color change is observed, the sample is judged compatible with the detection solution and the rest of the test is performed.

2. The second phase of the Corrositex® test uses appropriate indicator solutions to allow categorization of the test sample as Corrositex® Category 1 or Corrositex® Category 2 material.

Corrositex® Category 1 materials are typically strong acids/bases, while Corrositex® Category 2 materials are typically weak acids/bases.

3.The third step of the test is performed by applying the sample to the bio-barrier. When the chemical penetrates through or destroys the entire thickness of this biological barrier, it comes into contact with the CDS which then undergoes a simple colour change.

This colour change is observed visually and the time required for the colour change to occur is recorded.

Once the time taken for the sample to pass through the membrane has been recorded it is possible to assign the correct GHS category and/or UN packaging group classification for US DOT or EPA compliance, or use the data as a classification tool or to validate marketing claims.